CONTACT US

|

Wechat

WeChat:+8605925523433Wechat QR code,Contact us

WeChat:+8605925523433Wechat QR code,Contact us

SG450C-F multi-lane back-sealing powder packaging machine

Detailed parameters and configuration

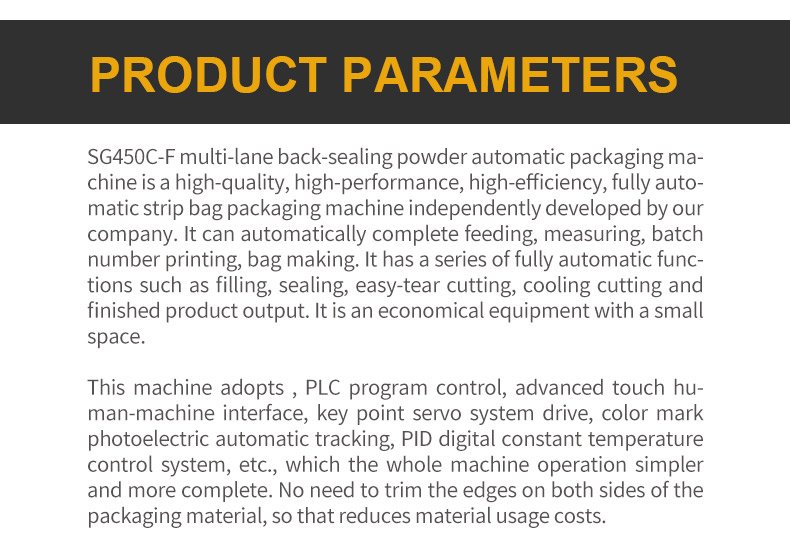

Equipment introduction

SG450C-F multi-lane back-sealing powder automatic packaging machine is a high-quality, high-performance, high-efficiency, fully automatic strip bag packaging machine independently developed by our company. It can automatically complete feeding, measuring, batch number printing, bag making. It has a series of fully automatic functions such as filling, sealing, easy-tear cutting, cooling cutting and finished product output. It is an economical equipment with a small space.

This machine adopts high precision, PLC program control, advanced touch human-machine interface, key point servo system drive, color mark photoelectric automatic tracking, PID digital constant temperature control system, etc., which the whole machine operation simpler and more complete. No need to trim the edges on both sides of the packaging material, so that reduces material usage costs.

Composition

Classification parameters SG450C-F

Scope function

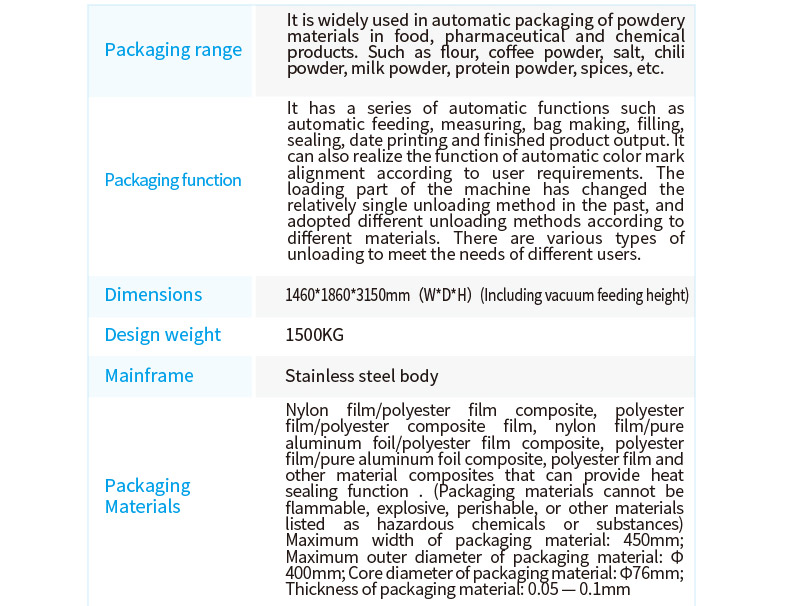

Packaging range

It is widely used in automatic packaging of powdery materials in food, pharmaceutical and chemical products. Such as flour, coffee powder, salt, chili powder, milk powder, protein powder, spices, etc.

Basic structure

Dimensions Width*Depth*Height 1460*1860*3150mm(含真空上料高度)(Including vacuum feeding height)

Design weight 1500KG

Mainframe Stainless steel body

Packaging material parameters

Packaging Material requirements

Nylon film/polyester film composite, polyester film/polyester composite film, nylon film/pure aluminum foil/polyester film composite, polyester film/pure aluminum foil composite, polyester film and other material composites that can provide heat sealing function. Maximum width of packaging material: 450mm. Maximum outer diameter of packaging material: Φ400mm. Core diameter of packaging material: Φ76mm. Thickness of packaging material: 0.05 — 0.1mm

Maximum single film width 120mm

Maximum bag length 180mm

Device parameters

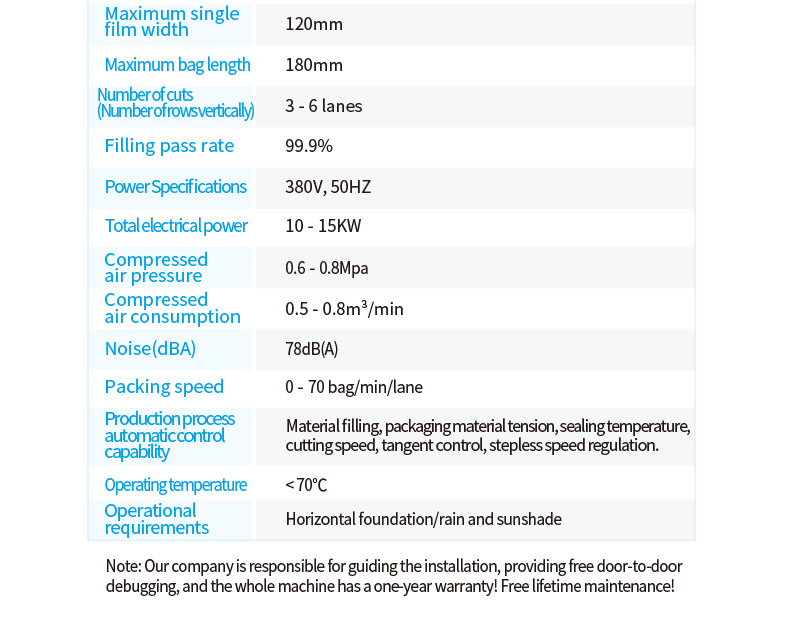

Power Specifications 380V, 50HZ

Total electrical power 10KW-15KW

Compressed air pressure 0.6~0.8Mpa

Compressed air consumption 0.6-0.8m³/min

Noise(dBA) 78dB(A)

Packing speed 0-70 bag/min/lane